When someone turns on the heating or turns on the hot water tap, they probably don’t know where the natural gas they are using comes from. Nor do they probably know what the process is it has gone through or the path it has taken to become a safe and efficient energy source. In this article we will tell you everything you need to know about the journey gas takes, from its origin to its final destination.

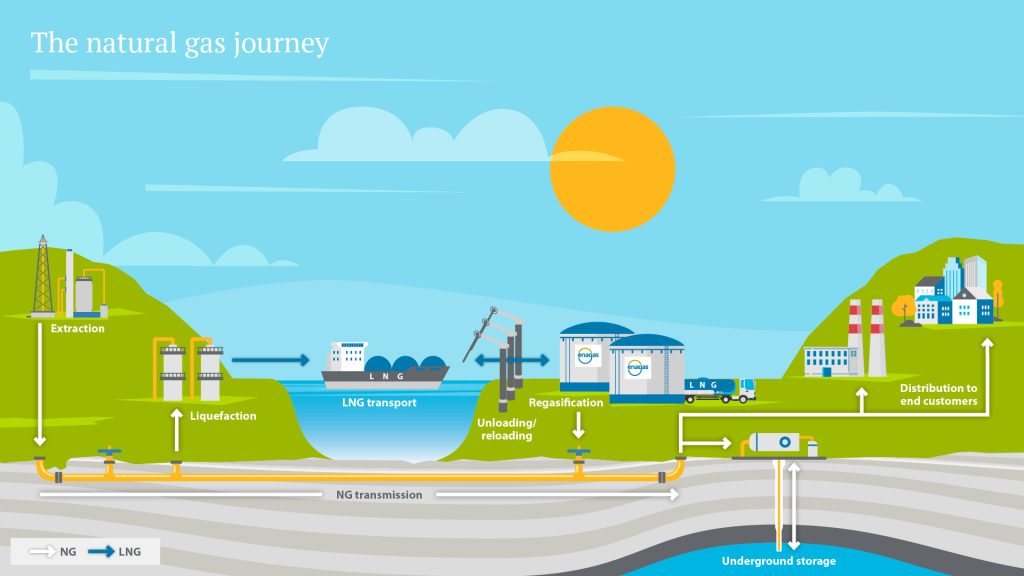

Natural gas is the result of the decomposition of organic material that has been trapped in gas fields for millions of years. When they are uncovered– onshore if it is below solid ground and offshore if it is below the sea – companies proceed to extract them. It is at this point that gas begins its journey to meet the demand of industry and households.

In the case of Spain, which imports almost all the natural gas it consumes, this comes from various sources, some of them thousands of kilometres away. The two main forms of supply are through pipeline connections such as the one linking Algeria to Almeria or through the arrival of LNG tankers unloading liquefied natural gas (LNG) from countries such as The United States, Nigeria or Qatar, to name just a few, in ports such as Sagunto (Valencia) and Huelva (Andalusia).

The two main forms of gas supply are pipeline connections or LNG tanker

Thanks to all this diversification, the Spanish gas system not only covers domestic demand, but also exports gas to other countries, helping to guarantee energy supply. And to achieve this, infrastructure is one of the key aspects.

Pipelines are made chiefly from steel and carbon. They possess characteristics such as elasticity, corrosion resistance and tolerance to high pressures during transit, whether underground or on the seabed.

LNG tankers are a widely used transport option to cover long distances between geographies that cannot be connected by pipelines. With this alternative, in liquefaction terminals, the gas is subjected to low temperatures (-160°C) to convert it into a liquid so that it occupies less volume. In this way, a larger quantity can be transported than if it were in a gaseous state. That’s why this type of gas is known as liquefied natural gas (LNG).

Once the LNG carrier has arrived at its destination, it unloads the LNG at a regasification terminal. There, a vaporisation process is carried out using seawater, whereby the temperature is increased to restore the gaseous state. At this point there are three options: inject the gas into the pipeline network to transport it to its final destination, load it onto tanker trucks to send it to areas that are not connected to the pipelines, or leave it in storage at the regasification plant to supply it at a later stage according to existing demand.

Once the natural gas has arrived in Spanish territory, either through pipelines or methane tankers, Enagás is the company responsible for unloading, storing and transporting it to its final destination. To this end, it has an extensive infrastructure network that includes more than 12,000 kilometres of high-pressure gas pipelines, three underground storage facilities (in Huesca, Guadalajara and the coast of Bizkaia), six LNG terminals and around 20 compressor stations, among other facilities that guarantee the continuity of supply, as well as the safety of the gas and the infrastructures themselves.

The MCC manages the operation and supervision of the transmission facilities of the Spanish gas system, 24 hours a day, 365 days a year

Undoubtedly, the ability to coordinate this whole structure is one of the aspects that requires the most care. This is where the Technical System Manager (TSM) comes into play through its Main Control Centre (MCC). This is the nerve centre from where the operation and supervision of the Spanish Gas System transmission facilities is managed, in real time, 24 hours a day, 365 days a year.

The MCC gives the necessary instructions for the correct operation of each infrastructure, guaranteeing the supply of gas in the appropriate conditions. Each storage or connection is monitored there, so that the Spanish gas system operates in a synchronized manner as a single unit.

As the energy sector is a strategic sector for society, the MCC has, in addition to physical and IT security measures, two other back-up centres equipped with the same characteristics to be used in case the main centre suffers any type of incident.

All this coordinated work involving people, technology and processes allows for a continuous and safe supply of natural gas. A journey that ensures that anyone who needs it can turn on the heating or turn on the hot water tap wherever they are.